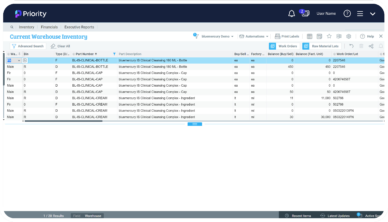

Streamline warehouse operations with real-time visibility and enhanced control

Priority’s highly scalable ERP warehouse management system utilizes unique customization features and advanced AI-based capabilities that allow companies to automate workflows, operate sophisticated warehousing and distribution processes, and quickly and easily adjust to changing customer demands and market conditions. With Priority’s WMS you can streamline your logistics cycle with real-time visibility, resulting in rapid and accurate responses to inventory movements and facilitating holistic control over warehousing operations and resource optimization.

See how Priority works for you.

Priority WMS Key features

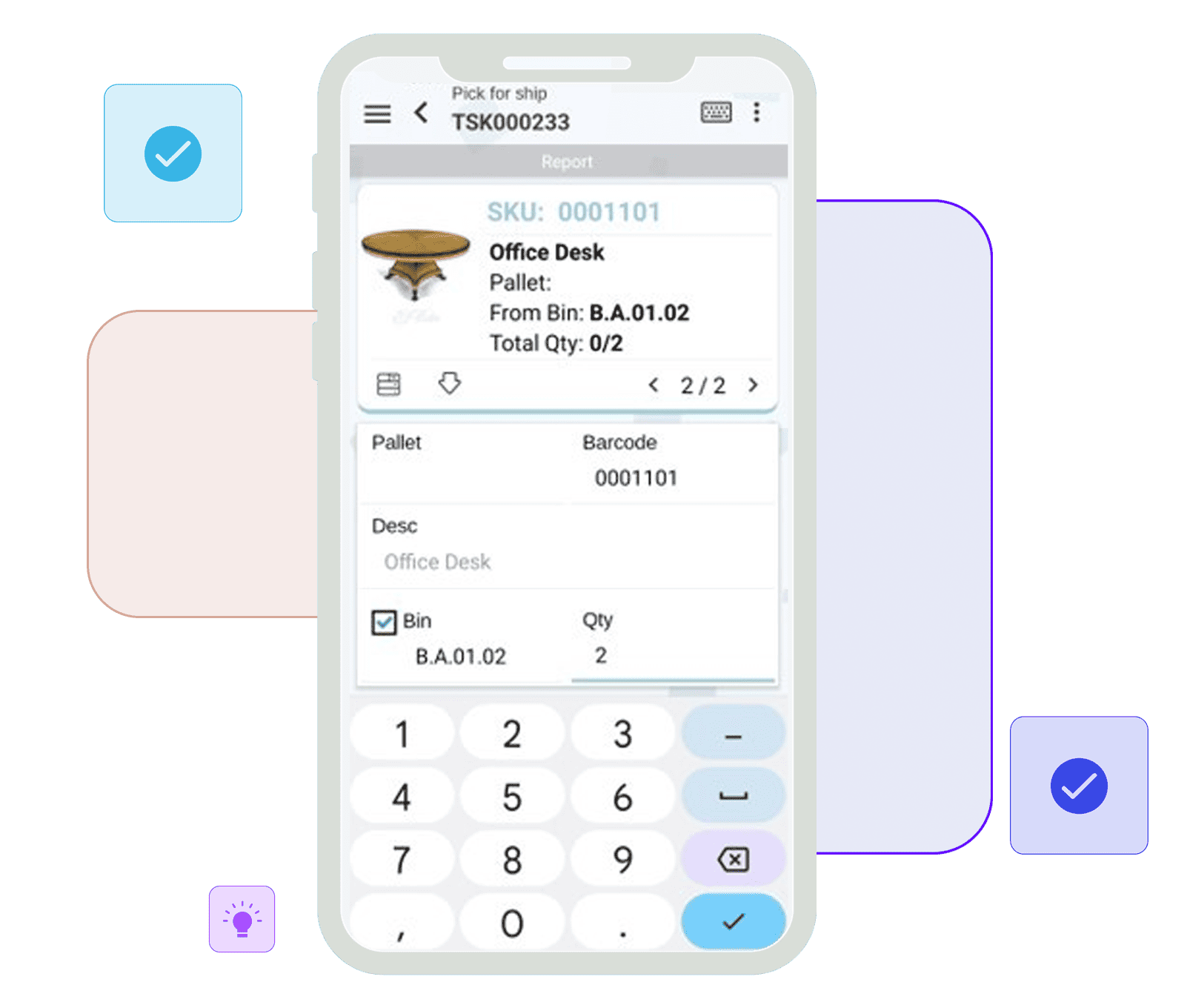

Pick, Pack and Ship

Priority’s WMS helps efficiently refine the picking, packing, and shipping stages of the logistics process. Effortlessly generate picking or shipping waves tailored to specific clients, orders, or order items, encompassing a task wave for packaging ordered items before shipping and a pick task wave for orders based on delivery routes and additional parameters.

Replenishment

Maintain adequate stock levels of high-demand items in the warehouse, guaranteeing that each picking location holds the ideal product quantity for a seamless and effective picking process. Sophisticated order-driven replenishment waves influenced by stock level policies, turnover tactics, storage zones, and more. Specialized hot replenishment and immediate replenishment from a “next-in-line” storage bin, triggered when warehouse personnel encounter an empty bin during a pick task.

Receiving and Put-Away

Effectively oversee the movement of received inventory from docking areas, kitting zones, or production departments to storage bins. Compare received quantities with planned amounts. Put-away tasks pinpoint available locations for ideal storage suggestions, considering various factors such as part number, part groups, and additional parameters.

Track and Trace

Achieve end-to-end traceability, from receipt to put-away, ensuing warehouse transfers, picking, and delivery. Advanced lot genealogy monitors lot components and preserves lot attributes during splits, merges, or transfers. Priority provides a sophisticated Delivery Tracking App, compatible with any mobile device or tablet, delivering complete functionality on-the-go, including driver documentation, digital signatures, and additional features.

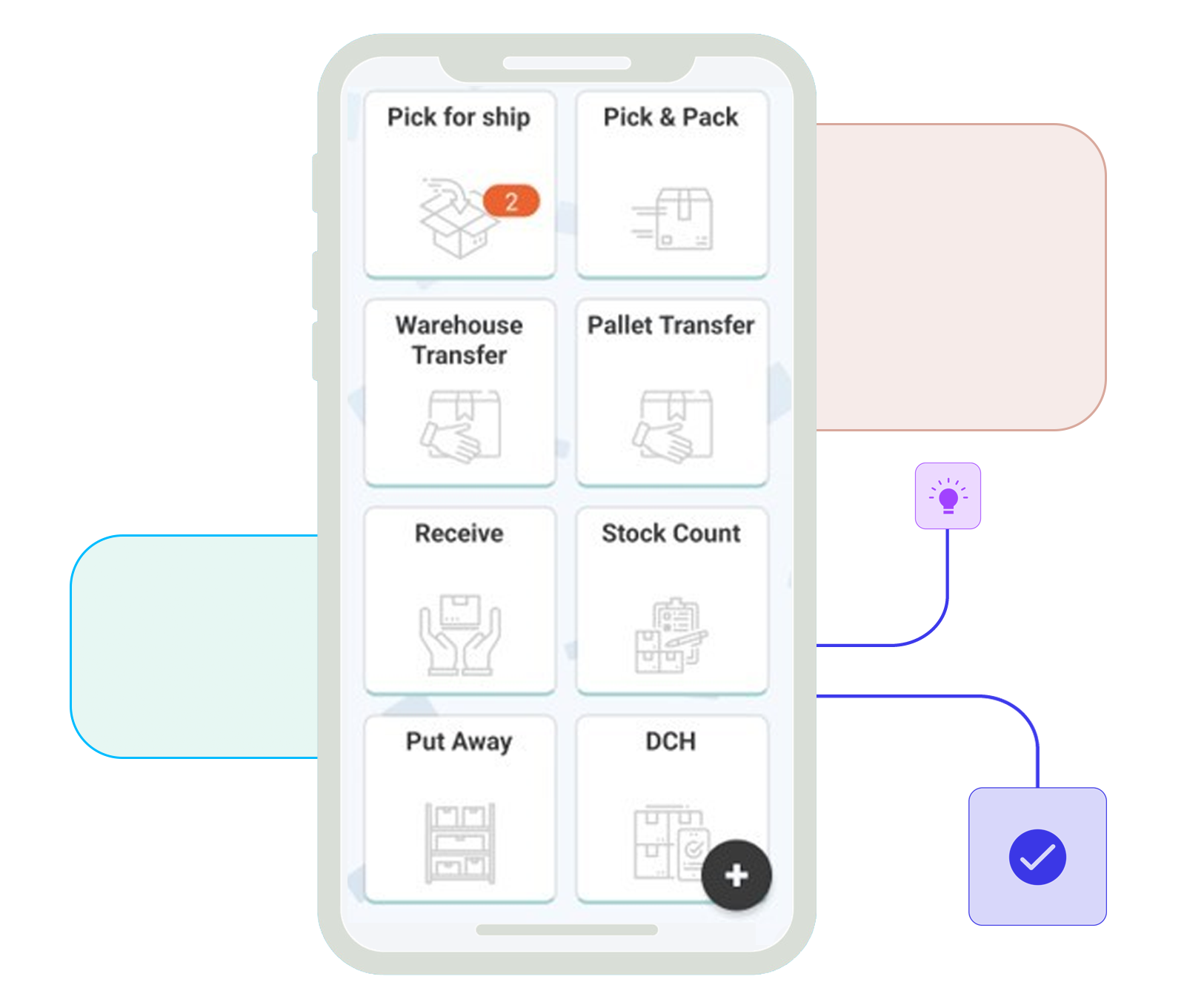

Mobile Devices, Barcodes, and RFID Tags

Comprehensive compatibility with mobile devices, barcode labels, and RFID tags enables warehouse staff to access pertinent information in real-time using a mobile device or tablet. This accessibility promotes well-informed decision-making and multitasking capabilities. Real-time task assignment notifications and execution tracking as work is carried out help to minimize processing duration and boost warehouse efficiency.