What is ERP for the pharmaceutical industry?

The pharmaceutical industry is a complex business network that manufactures, distributes, markets, sells, and researches drugs, medical devices, and diagnostic components. Each business operation has unique automation requirements to streamline its complex processes. The pharma industry relies heavily on quality testing and deals with stringent regulations that vary widely across borders.

A pharmaceutical enterprise resource planning (ERP) solution helps pharma companies streamline their operations, comply with regulations, manage batches and lots, implement strict serialization and tracking, and streamline supply chain management. In addition, a pharmaceutical ERP also facilitates research and development (R&D).

Drug companies also require ERP systems to manage finances, gain business insights, implement marketing campaigns, and offer customer support, just like any other business. In summary, a pharmaceutical ERP performs all the functions of a traditional ERP system but is tailored to meet pharmaceutical companies’ unique and complex needs.

The role of ERP in pharmaceutical companies

Pharmaceutical companies often consist of various entities that engage in different kinds of loosely related activities. ERP tools designed for the pharmaceutical industry help these entities improve operational efficiency and integrate disparate processes into a single platform. This helps reduce human errors, avoid production delays, eliminate data duplication, and ensure compliance with industry regulations and standards.

Pharmaceutical companies use ERP systems to manage, automate, and streamline various business processes. These include standard business processes like financial management, batch management, supply chain management, and production planning. However, the role of ERP in pharmaceutical companies goes deeper. It also helps automate and streamline processes like research and development and ensures compliance with various regulatory bodies. ERPs can help optimize other functions, such as clinical testing, drug discovery, and treatment response monitoring.

ERP systems help Pharmaceutical companies gain a comprehensive view of their product lifecycles, empowering them to make data-driven decisions that increase revenue and profits while improving patient outcomes.

What ERP modules do pharmaceutical companies need?

Manufacturing Module

First and foremost, a majority of pharmaceutical entities are manufacturers — both large and small.

From manufacturing drug packaging such as blister packaging, ampoules, and vials to manufacturing tablets, syrups, and other drugs, pharmaceutical companies have a lot on their plates. They also need to manufacture advanced surgical, diagnostic, and medical devices. These items require a software solution that does more than a regular manufacturing execution system (MES).

A pharmaceutical ERP synthesizes the functionalities of a manufacturing execution system with features that are specific to pharmaceutical manufacturing.

Batch and Lot Tracking Module

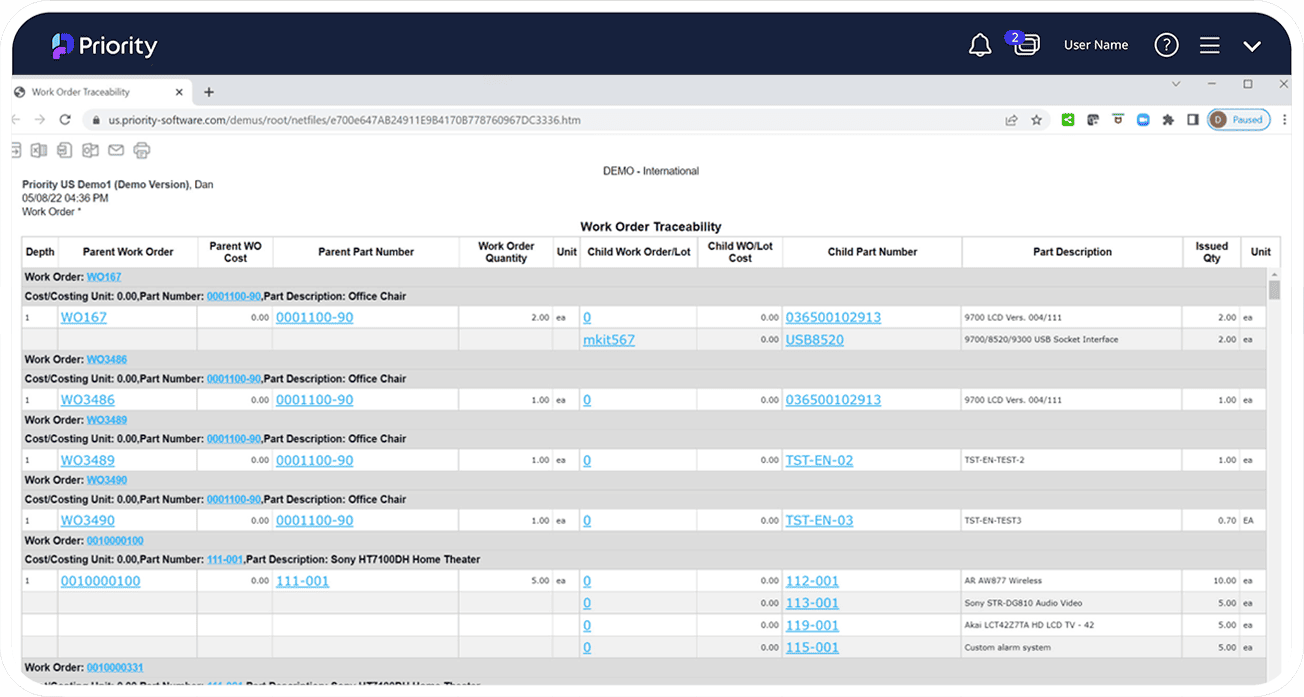

A Batch and Lot Tracking module helps pharmaceutical manufacturers remotely monitor individual item batch numbers.

This helps them keep track of each item from when it is about to be manufactured until it reaches the healthcare provider’s patient.

Pharmaceutical businesses can make informed decisions related to sales and marketing, inventory management, and even product recalls, as every item can be traced back to its source, right down to the vendor from where specific chemicals or components were purchased to manufacture a particular drug or device.

Quality Control Management Module

Drug companies must ensure that their drugs and healthcare devices are therapeutically safe and effective. Hence, quality control standards and compliance requirements are stringent.

A Quality Control Management Module automates several operations. It helps ensure that every step of the production process is tracked, monitored, and evaluated so that every item that is released into the market is safe and effective.

Most importantly, a Quality Control Management module keeps historical data of the production process so that when fraudulent claims are made, the business has proof to safeguard itself.

Compliance Management Module

Pharmaceutical companies across the world have multiple regulations to adhere to.

Compliance is essential to retain manufacturing and distribution licenses and avoid potential lawsuits.

The Compliance Management Module gathers all necessary information by closely sharing data with the Quality Control Management and other modules. This helps pharmaceutical companies to automatically send accurate and error-free compliance reports to agencies and authorities.

The Compliance Management Module also assists in remotely meeting various industry standards and regulations across borders.

Supply Chain Management (SCM) Module

The pharmaceutical supply chain is a complicated set of events and operations that involve various third-party vendors, shifting demand forecasts, and stringent quality standards.

Pharmaceutical ERP must have a dedicated Supply Chain Management (SCM) Module built for pharmaceutical companies.

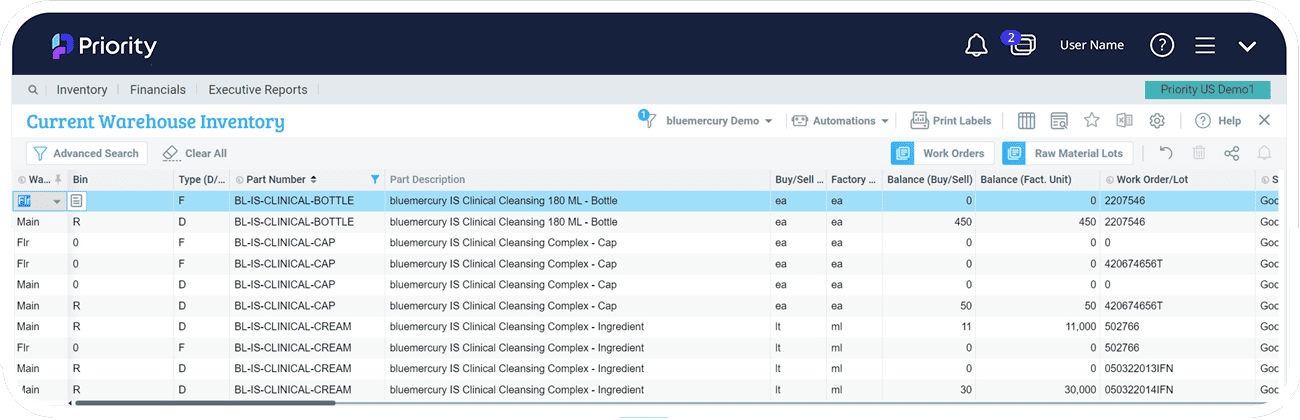

This helps them accurately replenish stock when necessary and avoid problems ranging from overstocking and understocking to the expiration of critical ingredients required to manufacture drugs.

They also help reduce the cost of procurement by choosing the most cost-effective vendors available in real time.

Serialization Module

Serialization gives each item a unique number that can be tracked and monitored. The main benefits of serialization in the pharmaceutical environment are improved inventory management, the ability to recall products when something is amiss, and compliance with various rules and regulations.

A serialization module helps pharmaceutical industries achieve all this while catering to customers’ needs.

For instance, it lets customers know when a particular item will expire and gives them the power to raise complaints when dissatisfied with the drugs.

It also shares data with other modules, such as compliance, supply chain, etc., to give pharmaceutical manufacturers the power they need to respond to various queries.

Research and Development (R&D) Module

An ERP collects enormous amounts of data that can help further research and development (R&D) activities. A dedicated R&D module bolsters the ability of an ERP to help.

Pharmaceutical companies test out new drugs, arrive at new drug formulations, and conceive surgical and medical devices. R&D modules assist in data collection, testing hypotheses, conducting experiments, applying appropriate research designs, and finding suitable samples to represent the target population.

R&D modules also help analyze results and conclusions based on predictive and prescriptive analyses. In short, an R&D module is one of the most essential modules within a pharmaceutical ERP.

Financial Management Module

To begin with, a pharmaceutical company is a profit-making entity. It must ensure that the revenue figures are impressive at the end of each financial year.

Hence, managing finances and ensuring a record of all the spending and earnings are essential.

A Financial Management module helps pharmaceutical companies reduce costs in the long term by generating insights that help make forward-looking decisions.

These range from choosing the most affordable vendors to identifying opportunities to cut costs. In addition, they also help maintain a ledger and comply with tax-related regulations.

Business Intelligence (BI) and Analytics Module

A Business intelligence (BI) and analytics module help pharmaceutical industries gain rich insights about demand, market trends, and overall operational efficiency.

It also gives them an understanding of how competitors fare by generating competition insights.

As pharmaceutical ERP solutions collect large amounts of data, BI gets richer with time and creates valuable reports and insights that can be used across departments and teams.

Pharmaceutical companies can use the Business Intelligence (BI) and Analytics Module to understand how drugs perform in the market and if changes need to be made regarding sales and marketing campaigns.

In short, it generates accurate analysis and business insights that help pharmaceutical companies to remain profitable and relevant.