- Flexibility – Greater agility allows for faster response time to shifting market conditions and order demands

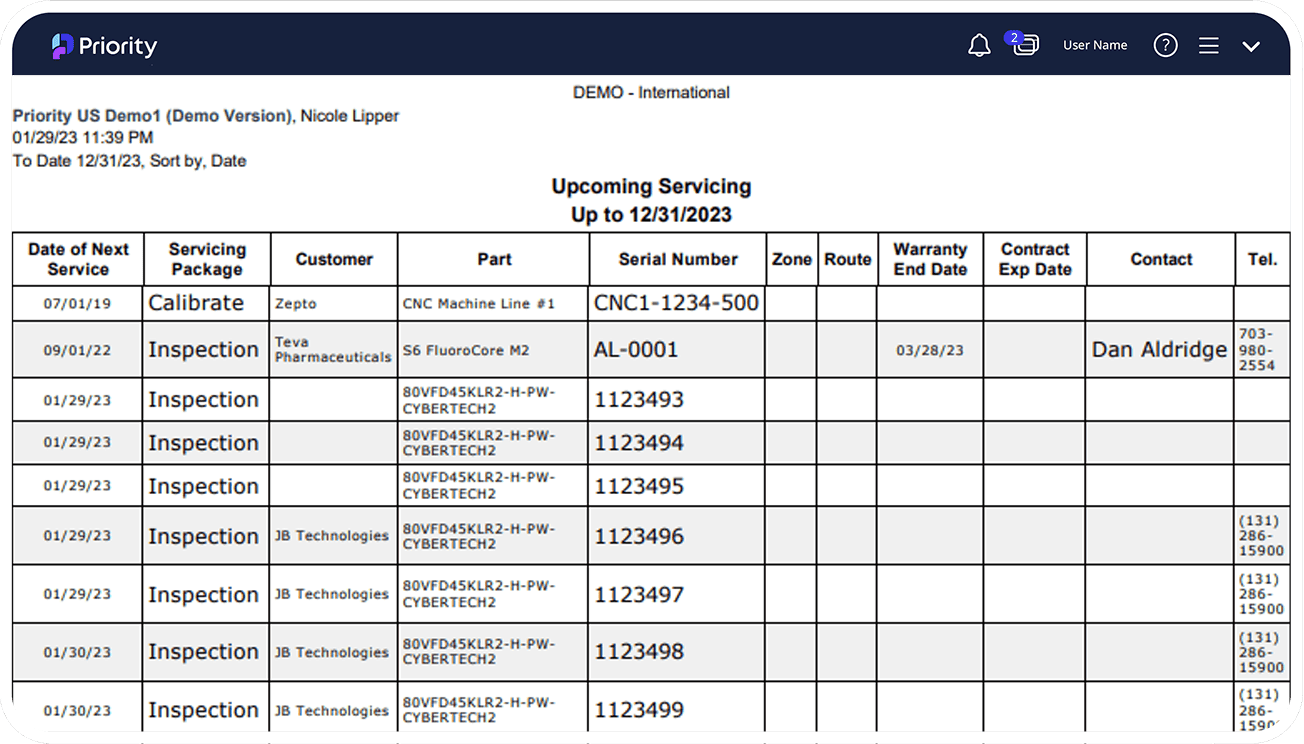

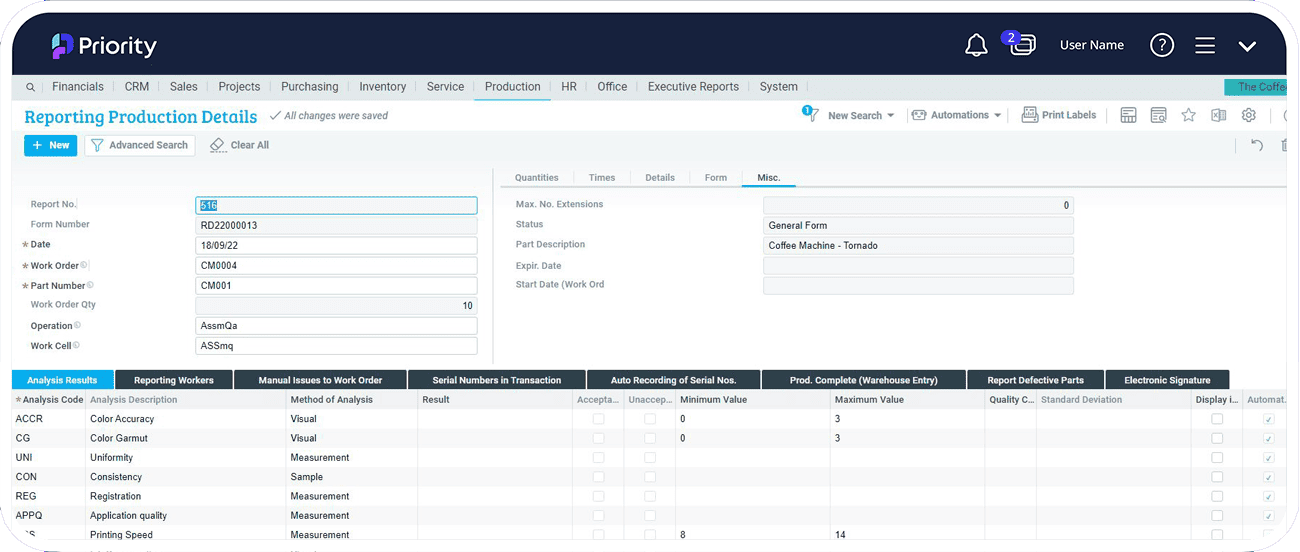

- Valuable Business Insights – A 360-degree, real-time view of the production processes with a wide range of reports and analyses

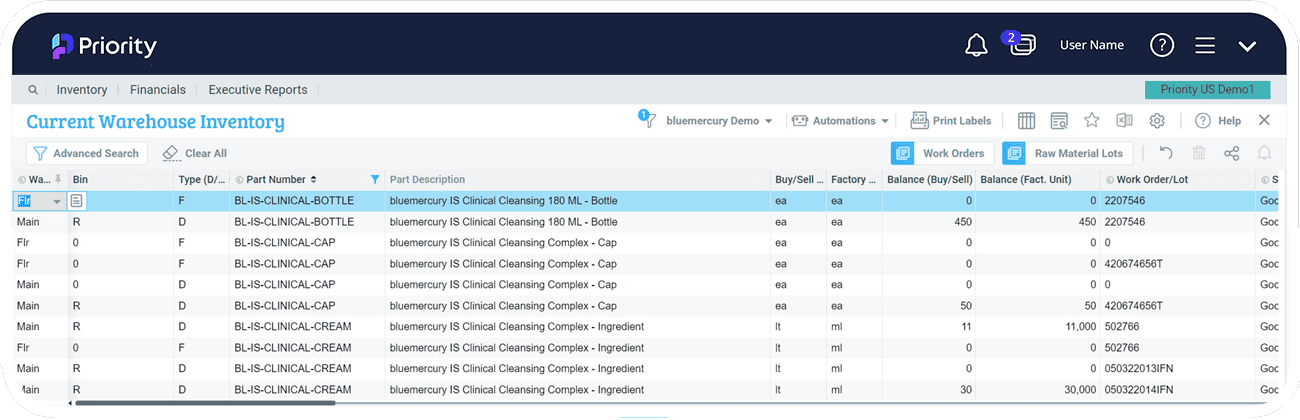

- Lower costs – Tight control of materials, machines and working hours leads to reduced costs

- Increase efficiency and enhance performance with automated business processes and intelligent workflows and production monitoring and tracking

- Improved flow of information – Enhanced collaboration among different teams and departments breaks down silos with the ERP serving as a single source of truth for the organization

We Understand Your Challenges

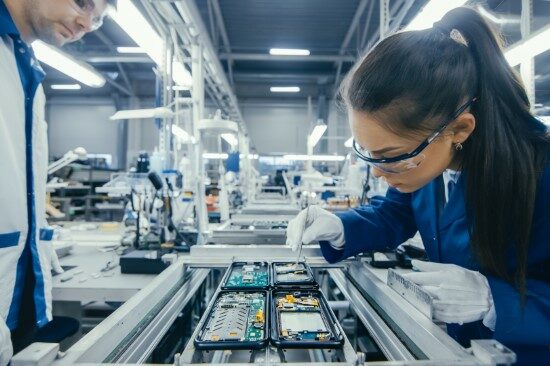

At Priority, we understand the many challenges facing the electronics manufacturing industry. From needing real-time information about the status of production, to moving new products out of the door faster and to providing customized solutions to demanding customers, electronics companies fight some of the toughest battles of any industry. Having worked with electronics manufacturers for more than 30 years, Priority ERP helps companies to both control and optimize operations while growing the business.

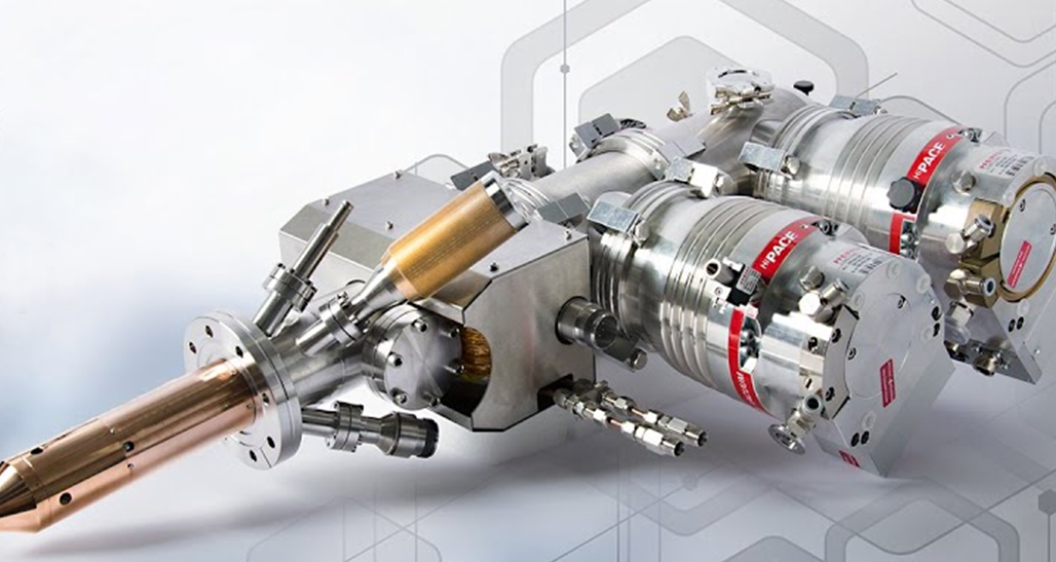

End-to-end electronics manufacturing management

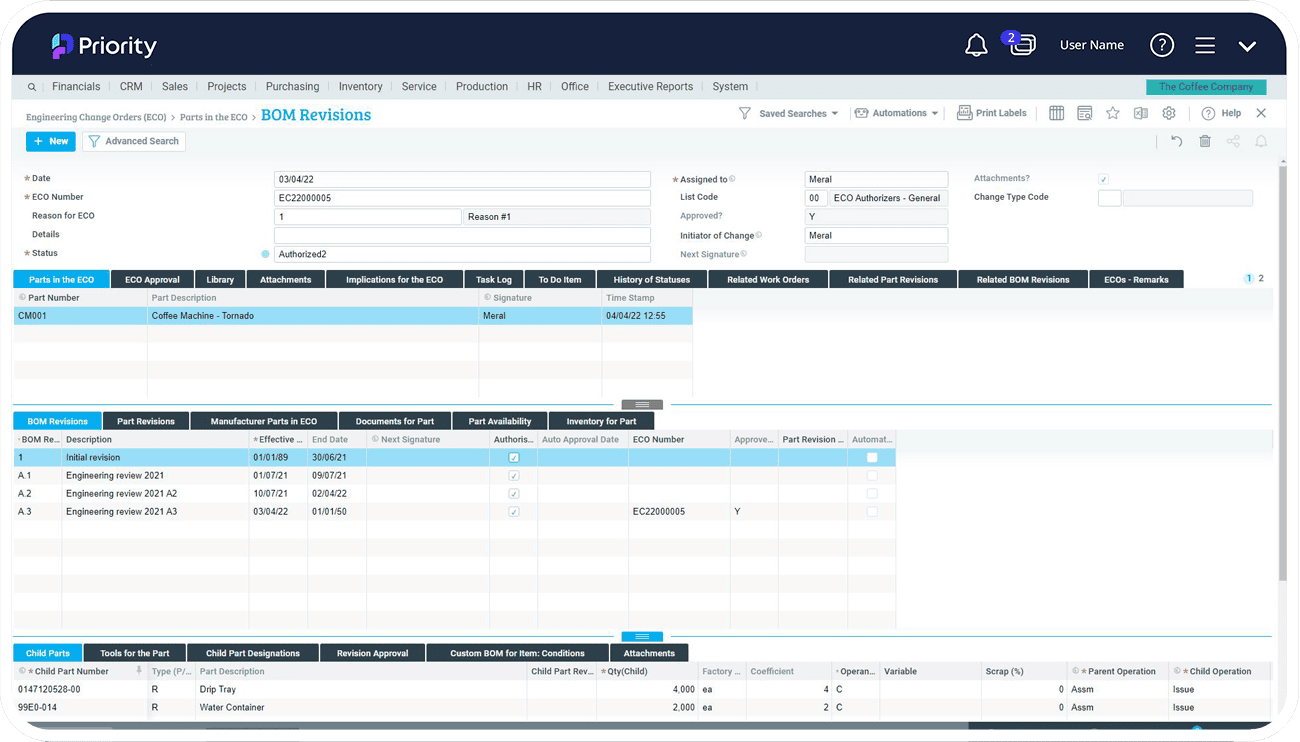

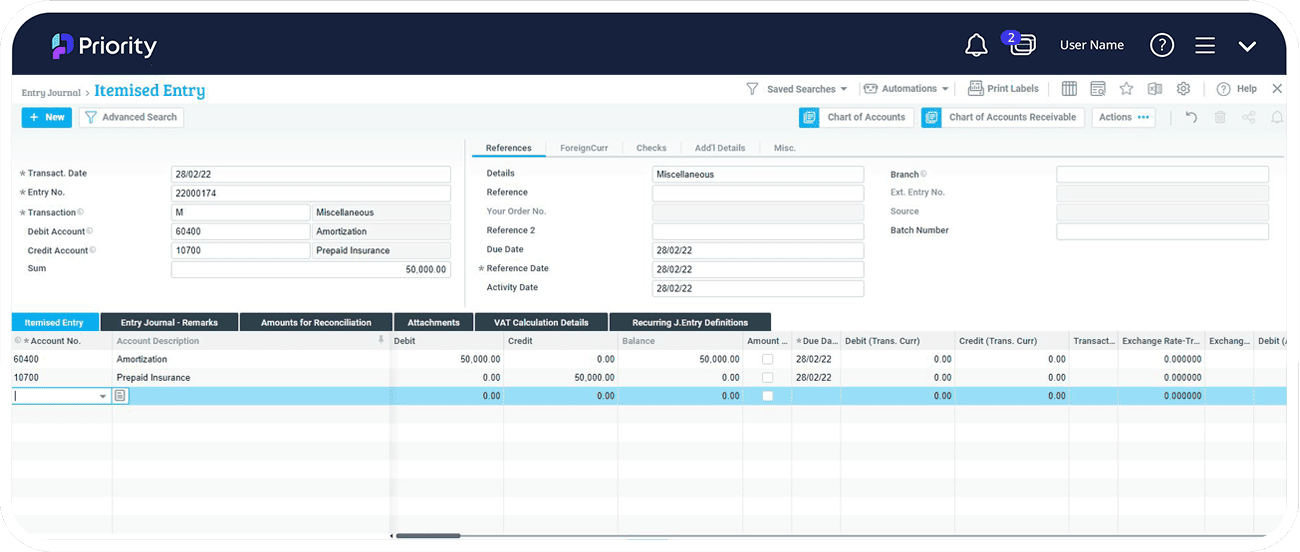

Priority’s ERP for electronics manufacturing offers an end-to-end solution that covers all aspects of the business, including manufacturing and supply chain, planning, quality assurance, inventory management, delivery, finance, sales, and post-sales activities. The ERP serves as a single source of truth with comprehensive visibility at every stage in the process.

Your competitive edge with Priority ERP for Electronics Manufacturing

Electronics ERP Key Features

“With Priority, we’re performing more tasks in real-time now than we could have ever hoped for using our previous solution. It’s Priority ERP’s real-time views of our inventory and manufacturing processes, with “always available, always accurate” reporting. This is how we’ve remained competitive, grown our business, and our brand worldwide.”

Kenneth Moreira, Information Technology Manager, Phillips Safety, Middlesex, NJ

Case Studies

FAQ’s

How can an ERP benefit electronics companies?

An ERP can help companies in the electronics industry manage and optimize their operations, from production planning and supply chain management to financials and customer relationship management. By providing a single, integrated platform for managing all of these processes, ERP helps companies to increase efficiency, reduce costs, and improve competitiveness.

How does ERP help electronics companies manage their supply chain?

ERP helps electronics companies manage their supply chain by providing real-time visibility into all aspects of the process, from supplier management to inventory tracking to order fulfillment. This enables companies to identify bottlenecks and inefficiencies and make more informed decisions about allocating resources.

What features should I look for in an ERP solution for my electronics company?

Some key features to look for in an ERP solution for electronics companies include the ability to manage the entire product lifecycle, real-time visibility into the supply chain, automation of complex processes and workflows, and tools for financial management and customer relationship management.