- Full visibility of product lines across the top floor and shop floor

- Improved agility and response times

- Seamless workflow synchronization

- Real-time alerts at every stage

- Simplify all your complex processes

Optimize manufacturing performance

Specifically designed for manufacturers, Priority Manufacturing ERP software provides a 360-degree, real-time view of production facility performance, tracking, and enhancement capabilities. Using a wide range of reports and analytics to help optimize operations, improve visibility and remove inefficiencies, Priority’s Manufacturing ERP software’s automated processes empower seamless and immediate synchronization between units, preventing delays and errors, from engineering all the way to production.

Stay ahead of the curve with the latest technologies

Priority supports the next revolution in digital manufacturing management, including IoT, AI and advanced robotics, with a dedicated REST API and a wide variety of innovative tools. The result is a super-flexible ERP for manufacturing companies that delivers powerful integrations, increased productivity, and profitability.

It's all about manufacturing agility

Built on a single platform, the Priority’s automated processes empower seamless and immediate synchronization between units, preventing delays and errors, from engineering to production. With Priority’s advanced planning and control capabilities, manufacturers can easily manage complex and critical supply chain management processes.

Priority gives manufacturers a real competitive Edge

Key Features

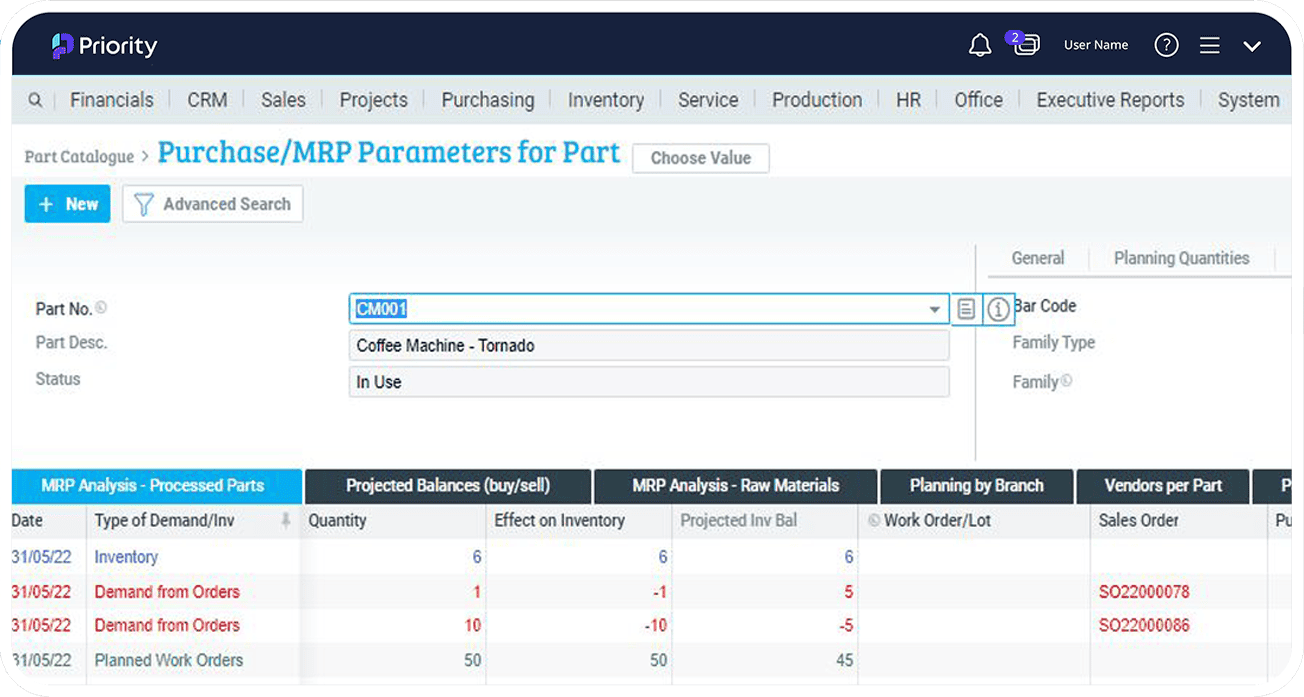

Material Requirements Planning (MRP)

A powerful production planning, scheduling, and inventory control system to manage your manufacturing processes, MRP determines material requirements based on sales orders, open work orders, or frequency of need. MRP helps you effectively plan your manufacturing activities, delivery schedules, and purchasing activities.

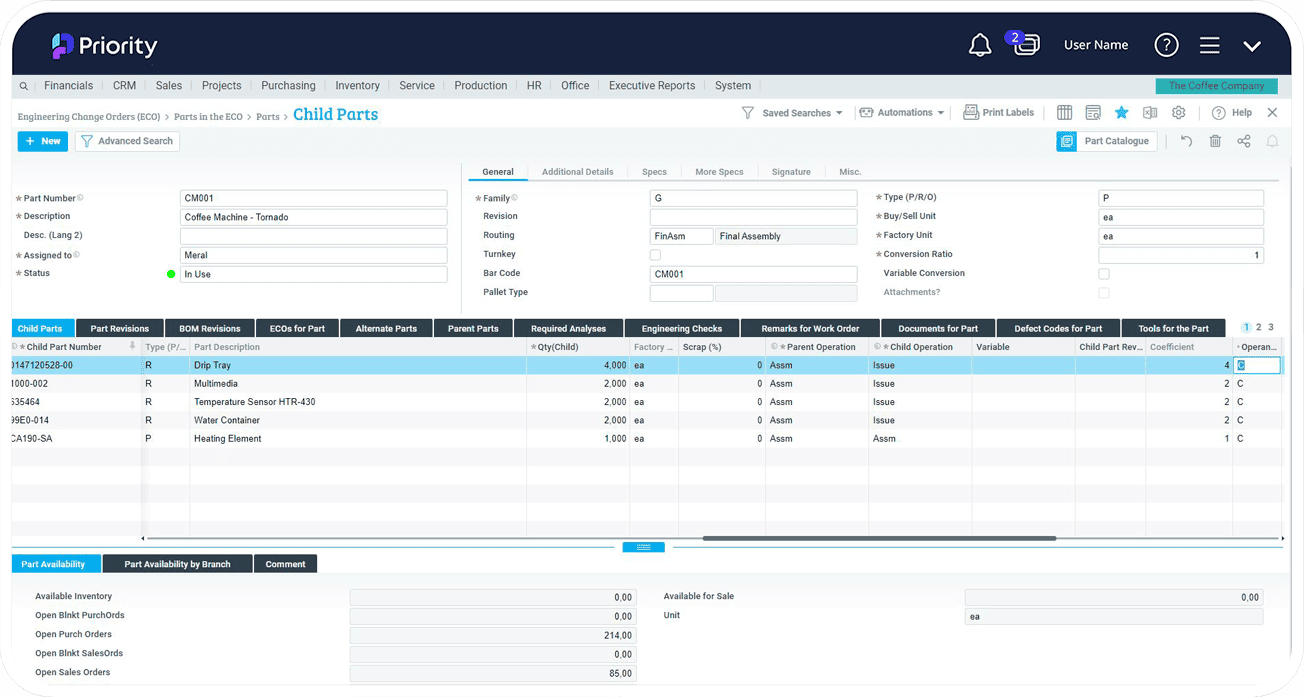

Product Data Management (PDM)

PDM is the process of capturing and managing your organization’s product-related data, so it can be reused in business processes, such as sales order management, purchasing, cost accounting, and logistics. PDM also maintains your manufacturing part numbers, Bill of Materials (BOM), and integrates with Product Change Control (PCC).

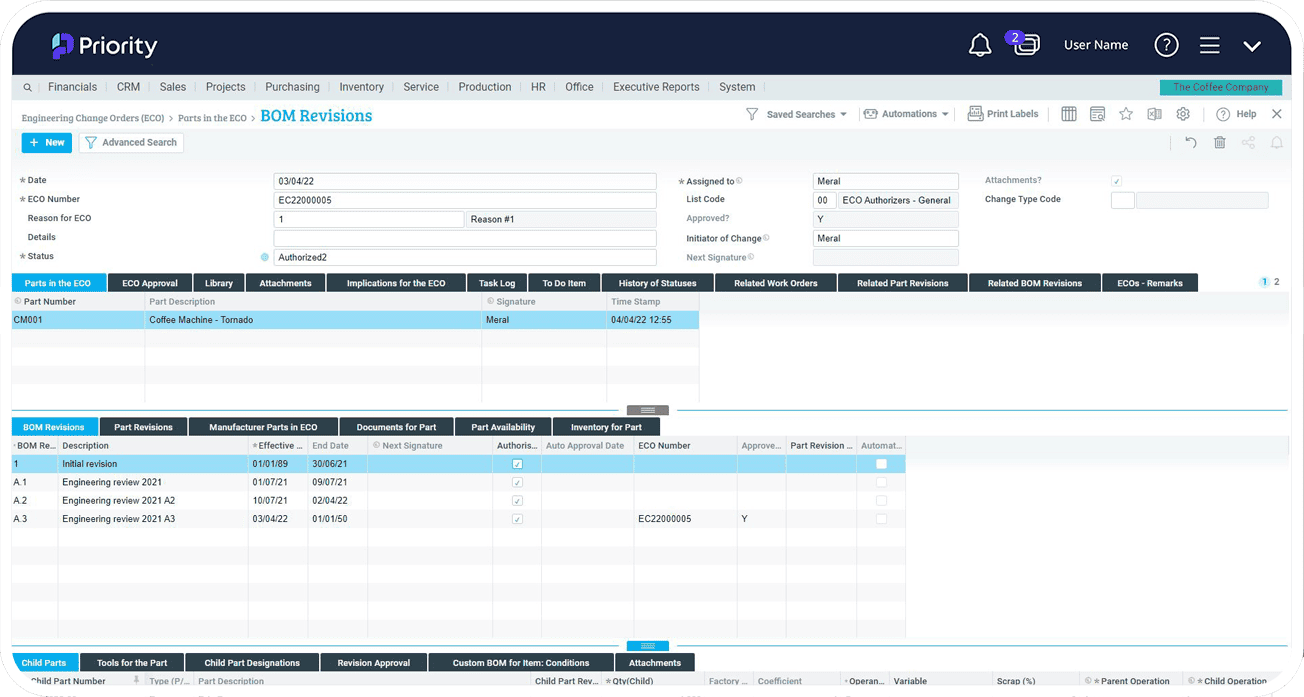

ECO Management and Revision Control

Priority’s ECO management, combined with tight revision control, delivers an immediate response to market demands, government regulations and safety issues, and service, functional and competitive requirements in your manufacturing process. ECO management tools optimize, organize, and track your entire approval process.

Multi-division Planning

Priority is built to serve multiple divisions for any size organization. Powerful manufacturing management tools and functionalities support organizations with multiple divisions and/or distribution centers. To best support your company’s needs, our manufacturing processes are easily customizable for multiple production control used in discrete, repetitive, and mixed-mode manufacturing.

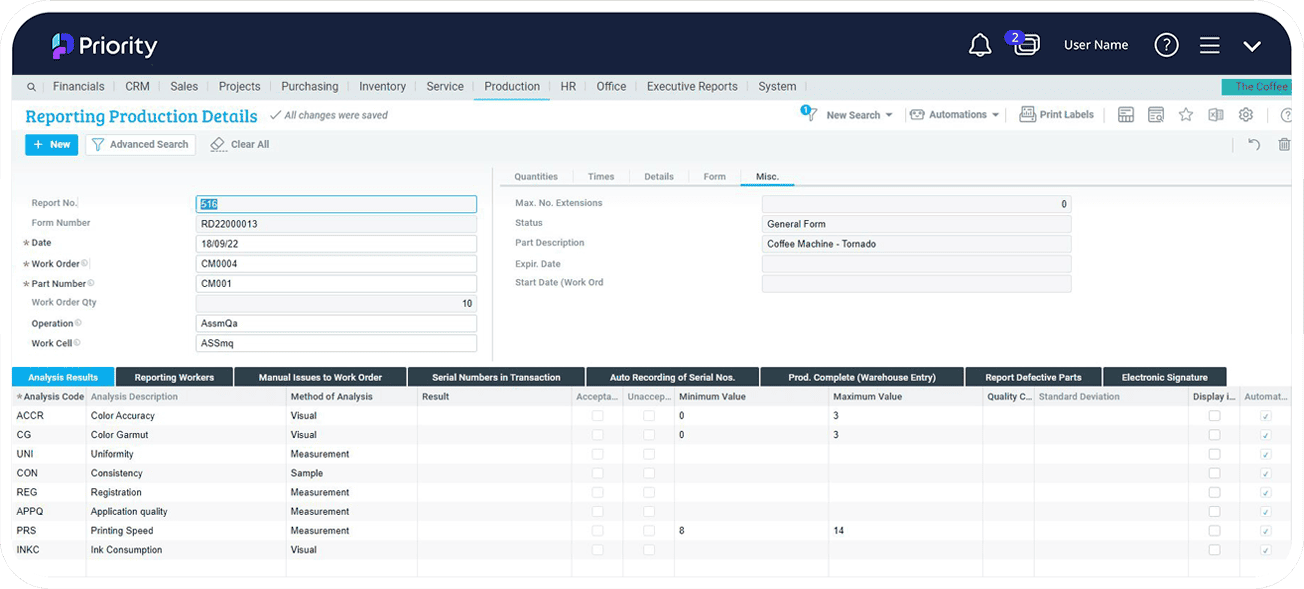

Quality Control and Assurance (QC/QA)

Key to any successful manufacturing process, Priority manufacturing is equipped with robust product-oriented QC functionality to detect and remove defects from your system, while QA is a systematic approach to ensure your ERP system process. Priority gives you the tools you need to fully automate QC processes and tests for serialized, lot or batch tracked inventory/non-inventory items. To support your QA activities, Priority ERP clearly defines test procedures and standards for inspection of purchased or outsourced components, inventory sampling, work order testing, and final QA.

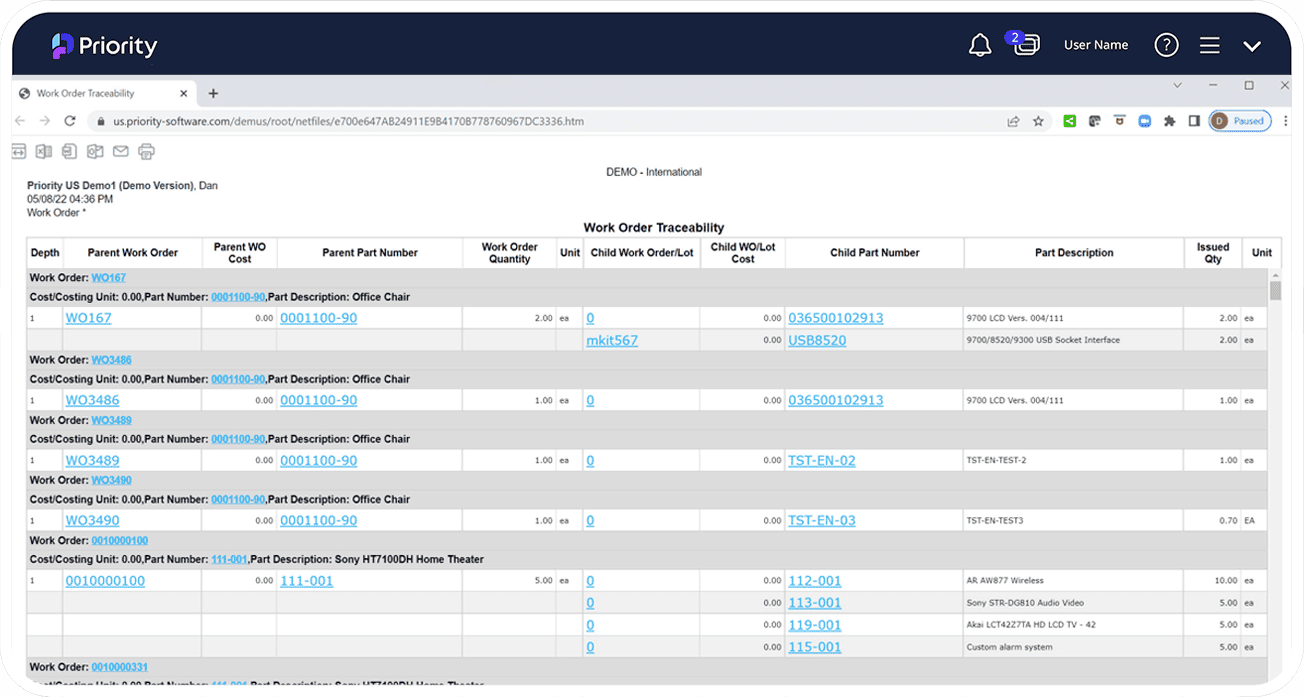

Serial, Lot Tracking and Traceability

If you’re in a highly regulated industry, your business demands stringent control over product tracking, and lot traceability. You need to be equipped to respond quickly to any defect or hazard, down to the individual parts or ingredients. Priority’s Serial and Lot Tracking ensures reliable management of material and product traceability through every stage in your supply chain, from receipt of raw materials, through delivery to your end-customer. You’ll have full control over parts as they move through your production process, and track serialized parts and their lot attributes throughout the entire part lifecycle.

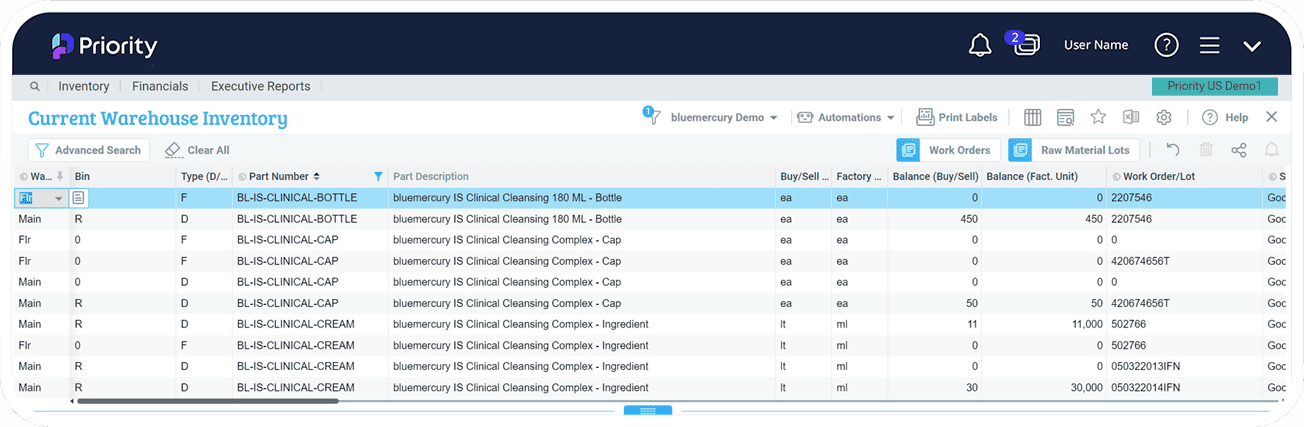

Inventory Control

The cornerstone of any successful manufacturing operation, inventory management and control is what drives your shop floor, supports raw materials’ handling, and helps increase your revenues. Maintain optimum inventory levels with real-time inventory analysis, save time and resources, improve service levels to serve current and future production needs, and manage tracking and traceability, with tight control on inventory replenishment.

Case Studies

FAQ’s

What is an ERP System in manufacturing?

Enterprise Resource Planning (ERP) is the process of integrating and delivering data and managing operations on a company-wide scale. In manufacturing, ERP is a dedicated software solution used to plan, manage, automate, operate, support, and report on operational business and production processes. To support the entire manufacturing process, a modern ERP seamlessly combines multiple operational business modules that manages and integrates a company's financials, supply chain, operations, commerce, reporting, manufacturing, human resources, and many more. Simply put, dedicated ERP solutions for manufacturers power the entire production process, from the shop floor, to the customer’s door, giving organizations a holistic view of their production facility, so they can run leaner, strengthen customer loyalty, and increase their overall efficiency, and productivity.

Why is ERP important for manufacturing?

ERP for manufacturing provides improved control over components inventory, more accurate demand-planning, streamlined production scheduling, and more effective coordination of distribution channels. This, in turn, enables companies to improve product quality, meet delivery schedules, and save on time, resources, and costs, as businesses will spend less time on individual resources and workforce. In the manufacturing sector, an ERP system takes the role of a middle man. It can be the defining factor in detecting what doesn’t work for a business, and what does. ERP operations manage all aspects of the manufacturing business - from automation of daily processes to on-ground inventory management, fewer overall costs, and more effective production planning.

How does ERP software work?

ERP software works by decreasing the number of resources required to run the business optimally, however, still ensuring profitability, and overall business improvement. An ERP system is different from a single application because it allows other enterprise modules of your company to work from a single, shared database. For the most part, ERP software depends on the kind of business it has been designed for.

However, all types of ERP software have an integrated data structure, whereby any changes within the manufacturing and/or supply chain will notify other departments, and individual users. This helps keep businesses in check, and in line, with real-time data insights to make more informed business decisions. Moreover, any collected data keeps the workflow going, and things running. ERP software also manages regular updates, where the goal is to have an automated flow of information, easily accessible by everyone in the company, and to power operational business processes without interruptions or delays.

What kinds of ERP software exist?

There are several types of ERP software solutions for manufacturing businesses, as follows:

• On-premises ERP. This type of ERP software runs on in-house servers located somewhere within the manufacturing facility, or at other locations managed by your company. An on-premise ERP solution offers the security and control of using your own IT infrastructure to connect your employees, processes, and systems, and require physical implementation to make system changes or upgrades. The risks of using an on-premise ERP include extensive IT budgets and system upkeep costs, difficulties in maintaining compliance, and disengaging your workforce, many of whom are or will continue to work remotely.

• Cloud-based ERP. This type of software runs exclusively online. Cloud ERP provides users with continuous support, updates, customization, and additional training. Moreover, the option tends to be less expensive, and less prone to system bottlenecks and downtime. However, cloud ERP is at risk of malware exposure.

• Hybrid ERP. A combination of on-premise and cloud-based ERP software systems, and entirely customizable. Depending on the business, these can include multiple hosting and physical hardware sites.

Does Business size matter when choosing an ERP?

Yes and no. The great thing about using an ERP system is its customizability. Some features are only intended for different-size corporations, and all vary in cost.

• Small businesses. Small manufacturing businesses don’t have the need for mogul company ERP packages. The ability to scale, integrate, and transfer information is simpler on a smaller scale. Having one base system through a cloud-based ERP will generally work best.

• Medium businesses. For manufacturing companies growing in size, integrating specialized workflow and scaling modules, is necessary. Medium-sized businesses with more capital are advised to invest in on-premise ERP software. This is due to both regulatory and legal policies. Depending on the policy, these can often prohibit extensive data storage on a single device.

• Corporations. For large businesses and corporations, ERP software is a must. It’s best integrated within the company and then upgraded, as and when needed. Hybrid and on-premise ERP offer far better business management and control. If ERP software has not yet been implemented, a hybrid system is recommended, as it ensures continuous scaling, seamless data transfer, and a steady workflow.

Does my Business need ERP?

Most manufacturing companies require the assistance of an ERP system. This is due to the nature of the business. Manual operation management, unfortunately, delivers inefficient results. The ideal ERP candidates include manufacturing businesses facing various pain points, such as a halt in production, slow or inefficient processes, lack of growth, and little or no security checks. For a seamless experience, aim at promoting growth first. This will prevent you from having to overhaul a broken or fragmented system later on.

What is the difference between “discrete manufacturing” and “process manufacturing” and does Priority ERP support them both?

Process manufacturing relies on creating formulas or recipes to produce a product, whereas discrete manufacturing assembles parts in a prescribed process to produce a distinct item. While discrete manufacturing creates products that are differentiated by individual units, process manufacturing does not. It is important to note that there are five basic manufacturing, process types: project, jobbing/job shop, mass, batch, and continuous. (batch & continuous = process manufacturing). Priority ERP supports both discrete and process manufacturing.