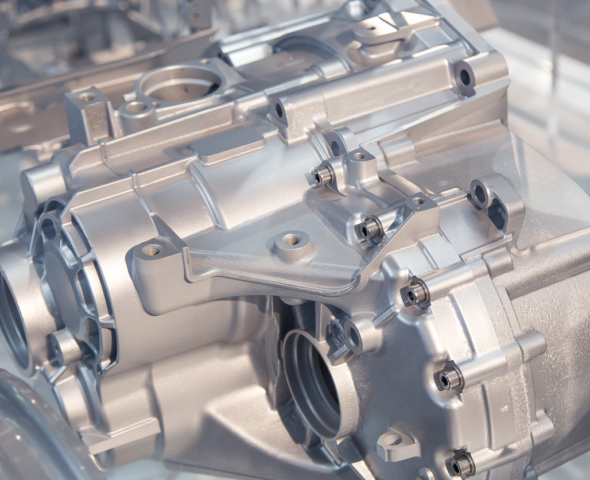

BSC Diecasting & Finishing is a long-established and highly innovative supplier of castings in the Midlands, UK.

For over 45 years they have been refining their processes to deliver the best castings with the best finish to the industry both in the UK & around the world.

Their 24,000 ft. facility features the latest diecasting equipment, which they cast & finish hundreds of thousands of items for various customers annually.